An Overview

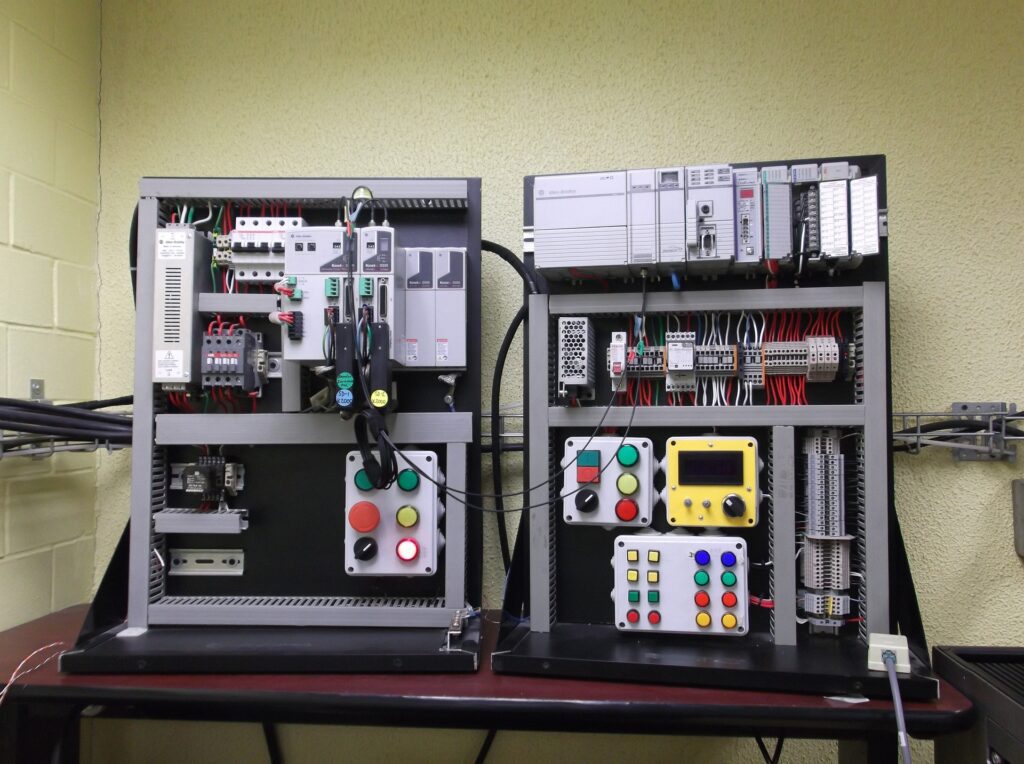

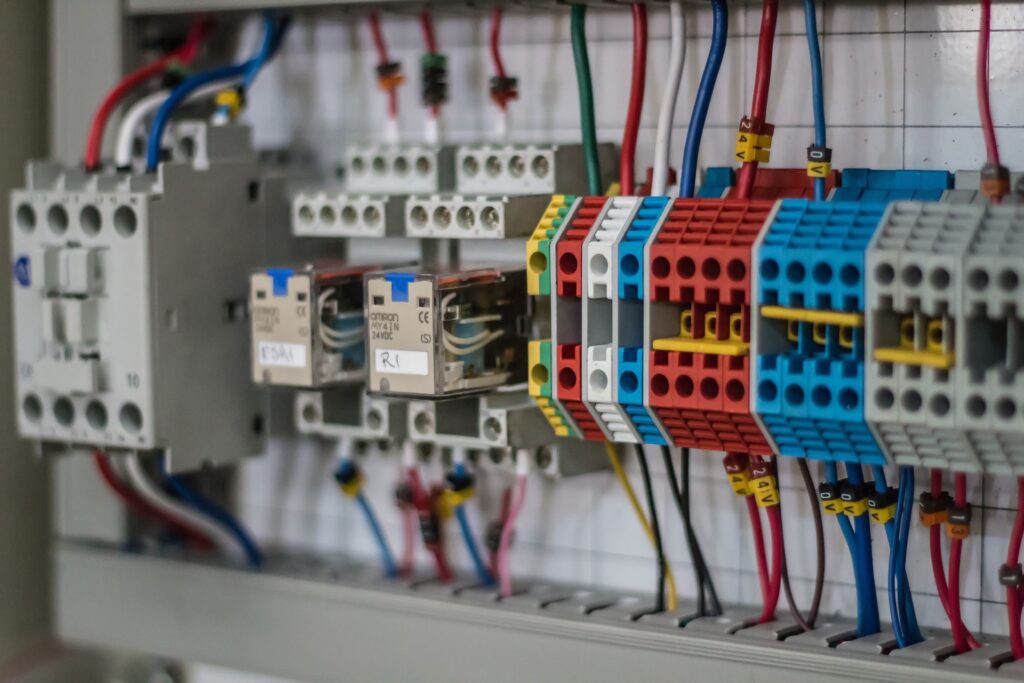

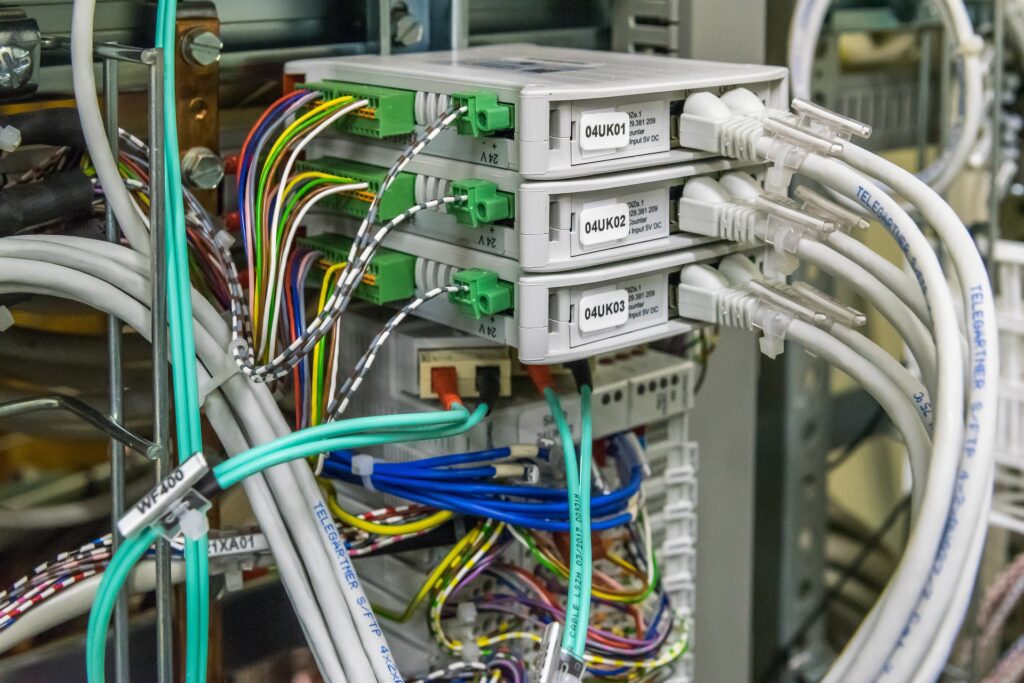

PLC Panels are small industrial computers with modular components designed to automate customized control processes. They are often used in factories and industrial plants to control machinery such as motors, pumps, lights, fans, and circuit breakers. With an integrated PLC Panel, you can monitor any process and receive data wherever and however you need it.

PLC Components

There are three main components to a PLC:

- Processor (CPU)

- Inputs

- Outputs

PLCs are powerful computers that take inputs, perform logic on them in the CPU, and then turn on or off outputs based on that logic.

Advantages of PLC Control

There are many advantages to using PLC Control, including:

- Rugged and designed to withstand vibrations, temperature, humidity, and noise.

- Interfacing for inputs and outputs is already inside the controller.

- Easily programmed and have an easily understood programming language.

- Very fast

- Easy to change logic i.e. flexibility

- Reliable due to the absence of moving parts

- Low power consumption

- Easy maintenance due to modular assembly

- Facilities in fault finding and diagnostic

- Capable of handling very complicated logic operations

- Good documentation facilities

- Easy to couple with the process computers

- Analog signal handling and close loop control programming

- Counter, timer and comparator can be programmed

Choosing the Correct Processor

When selecting a PLC processor, the number of I/O points is the most important criteria. Each PLC processor will only be capable of working with a limited number of I/O modules.

Another important criteria for selecting processors is memory size (for data storage or program storage) and performance (scan time depends on the processor). The size of the program is dependent upon the complexity of the control problem and the skill and style of the programmer. Therefore, a PLC with an appropriate memory size and speed needs to be selected based on the application.

PLC Panel Types

PLC Panels are available in several types to meet different requirements. Some of the types are:

- Purge and Pressurized panels

- Flameproof and Explosion Proof Panels

- SIL Safety PLC systems

- Distributed Control Systems

- IEC 61439 Type Tested Assembly panels

PLC Panel Specifications

PLC Panels may be specified by any possible combination of inputs and outputs. Some of the specifications are:

- Total Number of Points: Number of points is the sum of the inputs and the outputs.

- PLC I/O: Input/output signals the PLC can accept/provide

- Scan Time: Time required by the PLC to check the states of its inputs and outputs.

- Data Memory: Capacity for data storage

- Program Memory: Capacity of memory for control software

- PLC Programming Language: Ladder Diagram, Structured Text, Relay Ladder Logic, etc.

In conclusion, PLC Panels are a vital component in industrial automation, allowing for the efficient and reliable control of machinery and processes. With their many advantages and flexible options, PLC Panels can be customized to meet a wide variety of applications.